News

Cattle Abattoir Shipping For Zimbabwe-Mr. Paul Mpofu&Mr. James Machingaifa

Date: April 11, 2025

Customer: Mr. Paul Mpofu&Mr. James Machingaifa

Country:Zimbabwe

Project:3-Cattle-Per-Day Abattoir Project

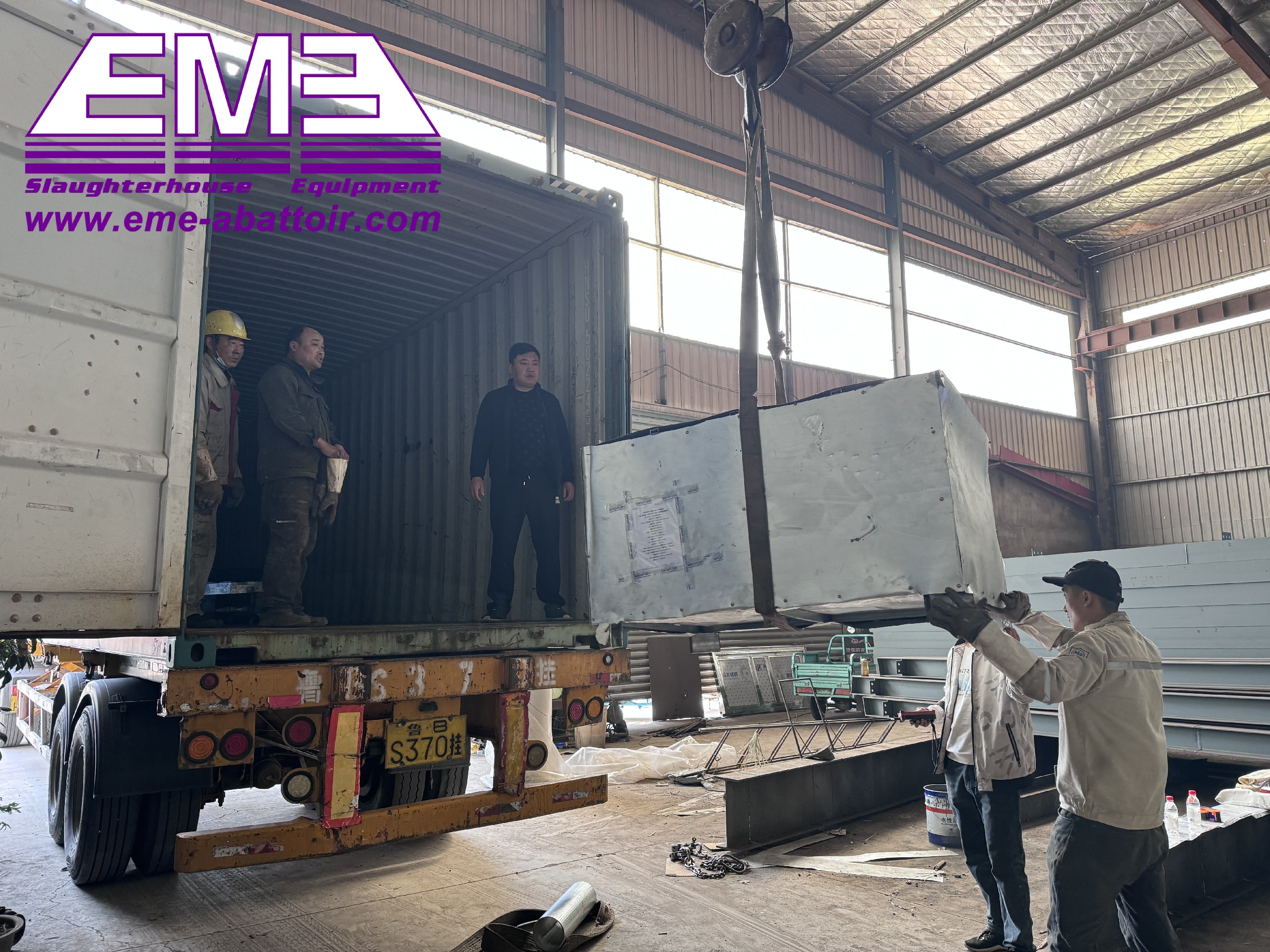

With Amy and the EME team’s professional follow-up, we’ve completed and shipped a customized full-set cattle slaughtering equipment project for Zimbabwe client, entering the delivery phase. This turnkey project covers a complete slaughter production line (stunning system, skinning machine, splitting saw, etc.), steel structure plant and prefabricated cold storage, upgrading from single equipment to whole-plant supply.

Made of food-grade 304 stainless steel per international hygiene standards, the line was inspected on-site by the client, who highly praised its quality, workmanship and our professionalism as "beyond expectations". All products are well-packaged for ocean shipping and have been batch-loaded into containers. We’ll offer on-site installation, commissioning and technical support. The project showcases our system integration capability and Chinese smart manufacturing’s competitiveness in Africa, and we’ll keep delivering premium meat processing solutions globally.